BEX JPL Air Atomizing Spray Nozzles use compressed air (or gas) to produce an accurately controlled liquid dispersion in applications where a conventional liquid spray nozzle would not be suitable.

The JPL Series are excellent products for new applications, and are suitable for replacing products in existing atomizing applications. Many of the JPL Series components are interchangeable with the products from other manufacturers.

This page will explain the many ways which Air Atomizer assemblies can be used, and how to select the best set-up for your application. For basic troubleshooting, please see our troubleshooting guide.

For further assistance, please contact the BEX customer support team, and we will be happy to help you directly.

Typical applications include humidification, cooling, air pollution control, coating processes, lubrication, curing, chemical dispersion, and many other uses.

A standard BEX JPL assembly consists of seven components that fit together to produce an atomized liquid spray pattern.

The JP Air Cap (2) and JL Liquid Nozzle (3) are the components that actually determine the spray pattern and liquid/air flow rates. We have arranged many of these Air Caps and Liquid Nozzles into a "set-up"(see How to Select a Set-Up), which makes it much easier to select a suitable choice for your application.

BEX JPL series nozzles and components are available in 303 stainless steel, 316 stainless steel and nickel-plated brass.

All BEX JPL Series products are designed to provide a wide range of performance flexibility, allowing the user to adjust the liquid air and feed to the set-up.

By adjusting the liquid and/or air source, a variety of spray droplets and atomization can be obtained. The performance tables below provide spray capacities at certain liquid/air flow standard conditions. These are not by any means the only possible results for each specific set-up.

If you know how much liquid flow you desire from the nozzle, but are unsure of the other operating parameters, the tables below provide a quick starting point to determine which set-ups are most frequently chosen to provide the liquid flow rate desired.

Each spray set-up consists of an air cap and liquid cap which provide a specific spray pattern, capacity and coverage performance. The set-up will produce comparable spray performance with any of the various bodies available.

Liquid and gas are mixed internally to produce a completely atomized spray. Available in Round, Wide-Angle Round and Flat Spray patterns.

Common Applications: Dust Control, pesticide application, humidification, cooling, coating and low viscosity fluids.

Liquid atomization is controlled by varying the air pressure without changing the liquid pressure. Effective for higher viscosity liquids and abrasive suspensions.

Typical Applications: Precisely metered applications, adhesives, coatings and viscous fluids

Fine or coarse droplet size atomization is produced by adjusting the air and liquid pressures. Finer atomization is achieved by increasing air pressure and/or lowering the liquid pressure.

2JTPL - 1/4"

Air (gas) and liquid inlets are both on top of this body, 90° from the nozzle outlet.

2JBPL - 1/4"

Air (gas) and liquid inlets are on the back of this body, 180° from the nozzle outlet.

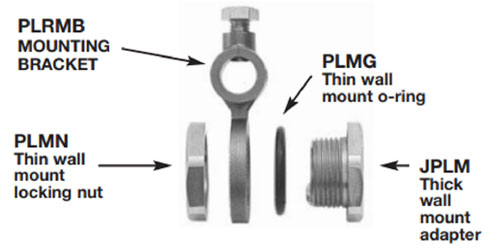

JPLM

Wall adapter replaces the cap retaining ring with a 3/4" MNPT adapter which allows mounting any JPL assembly to a thick wall (over 3/8" thick).

JPLN

Thin wall adaptation, simply add a PLMN locking nut and a PLMG o-ring to the JPLM thick wall adapter, and you can mount any JPL assembly to a wall less than 3/8" thick. (1-1/16" clearance hole required)

PLRMB

The rod mounting bracket allows for any air atomizing body to be mounted to a 1/2" diameter steel rod. Simply use the hardware from the thin wall mount (JPLN).

BEX Automatic Actuated Spray Nozzles can be fitted with any BEX spray set-ups to meet your atomizing needs. Liquid flow to the nozzle assembly may be either pressure, gravity or siphon fed. The flow is precisely controlled through an automatically operated air cylinder inside the body. For specific applications details please contact BEX.

Typical applications include: moistening, die lubrication, coatings, pattern lubrication, paper mills, and many others.

2JAPL -

Automatic Body

2JAFPL -

Automatic Body with Manual Shut-off

2JSPL -

Single Air Line Automatic Body

2JSFPL -

Single Air Line with Manual Shut-off

2JAX6PL - 6" Extension

2JAX12PL - 12" Extension

These extensions allow the spray tip to be positioned 6" or 12" away from the body.

JX6PL - 6" Extension

JX12PL - 12" Extension

These extensions allow the spray tip to be positioned 6" or 12" away from the body.

To order any JPL assembly, choose from the following: